Wheel loader performance strongly depends on how you select, maintain, and control the wheel loader for your projects.

You may need different types of loaders to operate different tasks. But, it isn’t an ideal choice for all project managers, right?

That’s why we at B&F Trading Sdn Bhd want to minimize your expenses wherever we can. Also, more construction heavy machinery means more maintenance costs. So, listen up!

Here are the tips to maximize wheel loader performance in the construction industry.

What is a construction loader?

Generally, a wheel loader is a type of heavy equipment machine commonly used in construction to load heavy materials such as rock, raw minerals, demolition waste, and wood.

This earthmoving equipment is an essential piece of machinery for any heavy industry for its productivity rate with lower maintenance costs compared to other construction equipment. Thus, construction loaders such as the WZ30-25 backhoe loader, ZL50 wheel loader, and XCMG wheel loader are ideal for construction, earth-moving, and agricultural purposes.

So how much can a wheel loader lift? A construction loader can typically lift two or three cubic yards whereas, mid-sized and larger loaders can lift up to 20 cubic yards or more!

More on Construction Wheel Loaders

Wheel Loader Bucket Guide

If you want to know the capacity of this heavy equipment, properly select the wheel loader bucket. This is determined by the required engine output, hydraulic flow capacity, and machine weight for your particular projects.

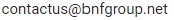

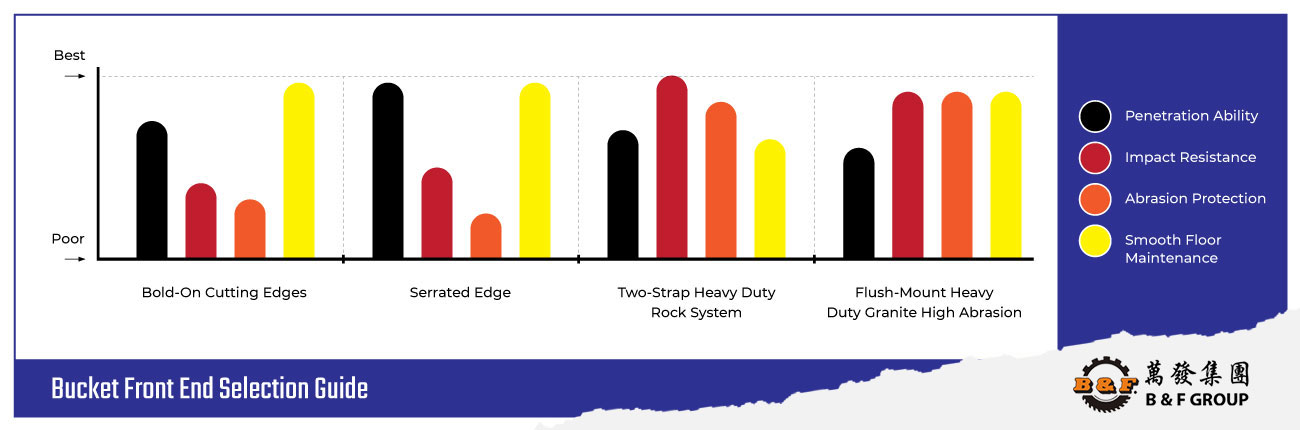

Also, by selecting the right bucket and front edge type, you can significantly boost productivity while reducing operating costs.

On the other hand, the bucket material of a wheel loader also helps improve overall performance. Refer to the chart below.

Operator Tips to Maximize Wheel Loader Performance

Increasing the work efficiency of construction loaders shouldn’t be complicated or costly. Instead, focusing on little details when operating them will suffice.

So, follow these tips when operating a construction loader for better productivity AND to minimize fuel consumption.

- Position the truck at a 45° angle to the front of the material to ensure minimum movement of the wheel loader.

- Straight-on approach to the front of the material to hit both sides of the bucket for a full bucket.

- Approach the material in first gear at a steady speed which can also prevent wheel spinning.

- Minimize contact between the ground and the edge of the bucket to reduce bucket wear and friction.

- Keep the wheel loader bucket parallel to the ground and slightly raise the bucket before curling it to lessen bucket-material contact.

- Practice good housekeeping by cleaning the floors which can help reduce material spillage.

How to Maintain Your Wheel Loader

1. Proper Care of Wheel Loader

Before looking at the key features of a wheel loader, you should understand how to use the machinery first. Get comfortable with the technology that is under the hood which can later help you handle preventive maintenances faster.

Moreover, it helps you reduce the overall costs and downtime of the machinery in the long run. Not to mention your operators will feel more confident using well-maintained heavy machinery.

2. Properly Use the Features of Construction Loader

Now, you can consider the wheel loader’s key features. A comfortable space to work and easy-to-operate components in the machinery will go a long way.

It surely does decrease downtime and increase productivity. These features include the ergonomic operator’s station, intuitive controls, suspension sets, and good visibility out of the cab’s window.

They may seem irrelevant to work efficiency but wheel loader operators know why we place importance on them.

Another way to decrease downtime during construction work is to increase working hours whenever possible provided the loaders are able to function efficiently. Thus, with the convenient features and well-maintained loader, you are sure to fully utilize this essential heavy equipment.

3. Reduce construction loader fuel consumption

Before deciding to invest in a wheel loader in Malaysia, inspect the quality and productivity that meets your project requirements, due dates, and travel speed.

The more miles per hour, the quicker the cycle times will be. When construction projects incorporate a wheel loader with other machinery like an excavator during times of underground work, there will be a greater consumption of fuel since more than one machinery is at work.

Therefore, the best way to handle fuel management is by applying auto-idle shutdown, fuel management systems or economy modes, and engine idle management.

4. Know your Wheel Loader Parts

Another feature that determines the work efficiency rate is the quality of operating ramps or inclines.

They contribute to better work productivity which brings to greater uptime. A higher speed transmission helps the operator to improve work productivity and reduce fuel costs for the inclines.

Wheel loader manufacturers use specific lubricants as catalysts. So, you need to understand how the systems of the inclines or ramps work.

Typically, these inclines or ramps consume time for regeneration purposes. Hence, the shorter the regeneration period, the lower the downtime for operations.

With that said, opt for a loader with a good cooling system and has easy access for cleaning. This way, components are well-maintained too.

Maximize Wheel Loader Efficiency the Right Way

The efficiency of a wheel loader can determine the productivity of construction workload.

All in all, make the most out of a wheel loader with the tips mentioned above so you’re protected from unnecessary costs. That’s why our Changlin machinery such as the Changlin wheel loader is your top choice for better performance.

Suggested read: Wheel Loader Operator Tips: Load Trucks with Better Efficiency

To find out more about our products, support, and services, inquire today to get your free consultation from our best heavy machinery advisors!